Observer-Dispatch: Albany, Marcy team up for ‘silicon-carbide corridor’

Published:

Tuesday, October 3, 2017 - 11:00

The Utica area’s next step into its high tech future starts with a 6-inch disc.

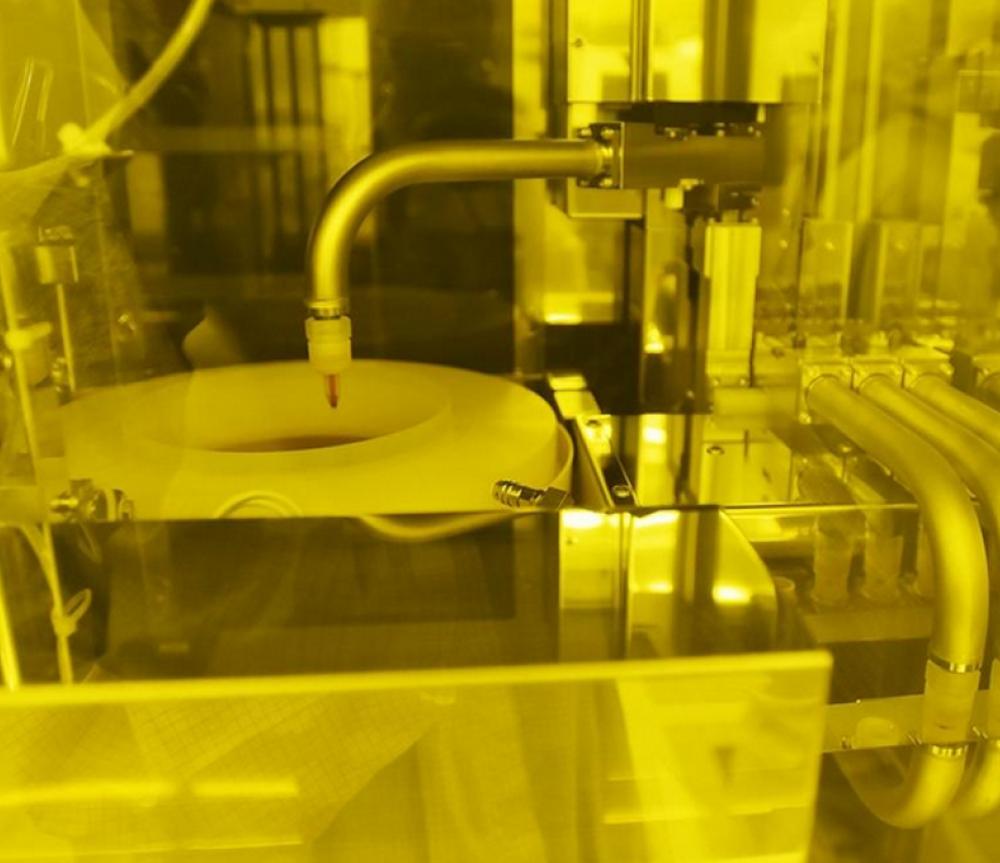

Workers at SUNY Polytechnic Institute in Albany are building the nano-sized future of electronic power on round, silicon-carbide wafers — chips that provide power for electronics.

Next year, Quad-C on the SUNY Poly campus in Marcy will start getting shipments of these wafers. General Electric workers will dice them into individual chips. Its partner, Danfoss Silicon Power LLC, will package them into power modules.

The silicon-carbide chips — SiC chips to the technically savvy — operate as switches for power management. They allow for greater efficiency because they can operate at higher temperatures with less cooling than silicon-based chips. That leads to energy savings because they don’t need fans or other cooling devices. So the systems they help run can be simpler and lighter, leading to savings in both energy and cost. These chips will ultimately be used in areas as diverse as aviation, electric cars, renewable energy and medical imaging.

“This is really the future of power electronics,” said Jeffrey Hedrick, vice president of the New York Power Electronics Manufacturing Consortium and a SUNY Poly employee.

Future of Quad-C

Quad-C isn’t operational yet. Contractors are working on the building. Most of the retrofit should be done by the end of the year, said Mike Hennessey, Danfoss’ site general manager.

Hennessey moved to Utica in early August, making him the site’s first permanent employee. Danfoss is in the process of hiring 13 engineers, and Hennessey said they should be in place by mid-October. Then Danfoss can focus on the next wave of hiring for jobs that have already been advertised.

Danfoss at Quad-C should be ready to get to work by April, but its first work will be internal jobs for Danfoss, products destined for sale in the U.S., making production in the U.S. more cost efficient than production in Germany, Hennessey said.

In Albany, at the other end of the “silicon-carbide corridor,” the production line is ramping up to full production and should begin delivering finished wafers to General Electric in January, officials said. The wafers are being produced through a partnership between SUNY Poly’s Albany campus and GE.

Hennessey said the first wafers from Albany will actually get shipped to Danfoss in Flennsburg, Germany, but Quad-C will take over the job before the end of 2018. Operations should transfer back to Marcy later next year, he said.

A SUNY Poly spokesman said some wafers will still to be sent to Quad-C to “support its ramp up to production,” however.

Albany’s role

In Albany, the blank wafers are being processed by about 45 workers in two shifts, about half SUNY Poly employees and half GE staff. By January, a third shift should begin. Over three years, production will ramp up until it reaches about 15,000 wafers a year, Hedrick said. Wafers get processed in batches of 25; the process takes between a month and six weeks to finish, he said.

The machinery is the most advanced available, as are the production processes that GE brings to the partnership, Hedrick said.

“This is without a doubt the world’s most advanced silicon-carbide line,” he said.

Hennessey, who used to work for IBM, visited the chip fab in Albany late last year and didn’t disagree with that assessment.

“I was amazed,” he said. “That is probably one of the highest tech set ups I’ve ever seen.”